Projekt von

Joby Thoppil

Begleitung

Anne Holtrop

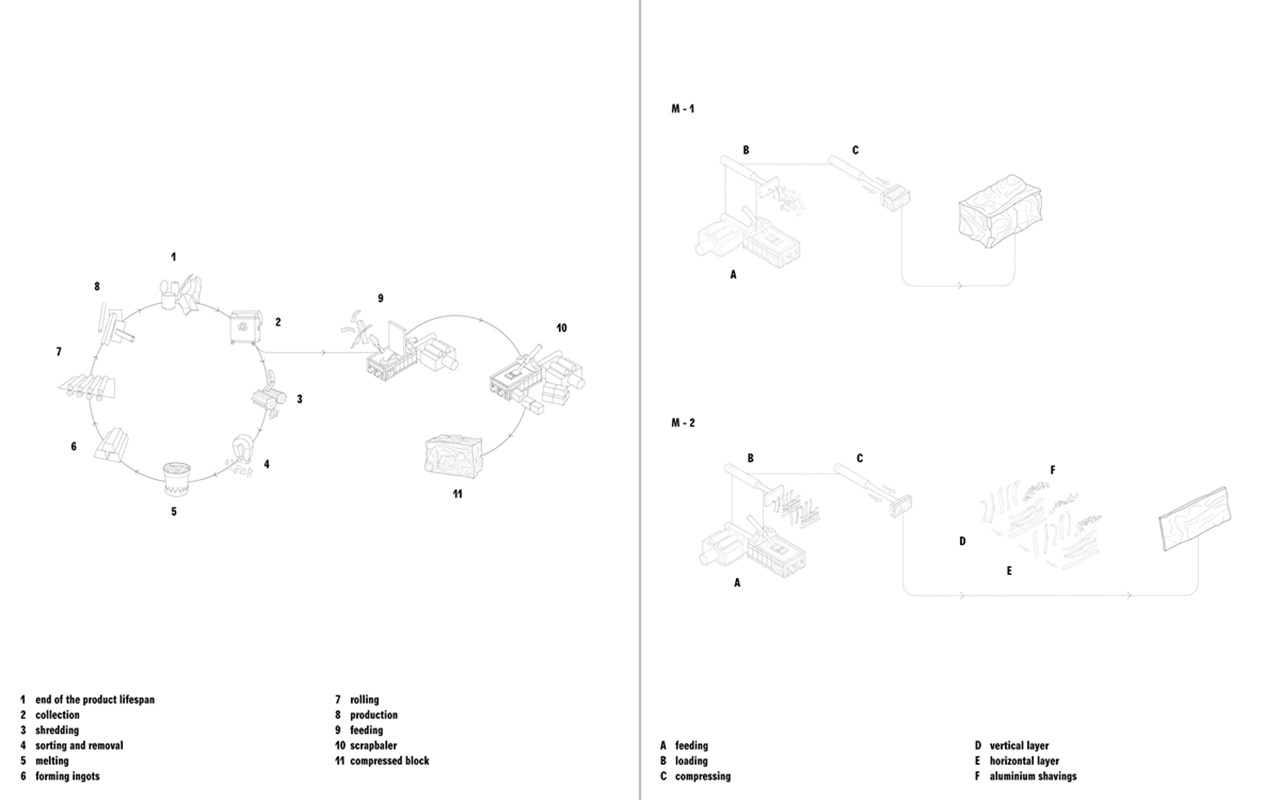

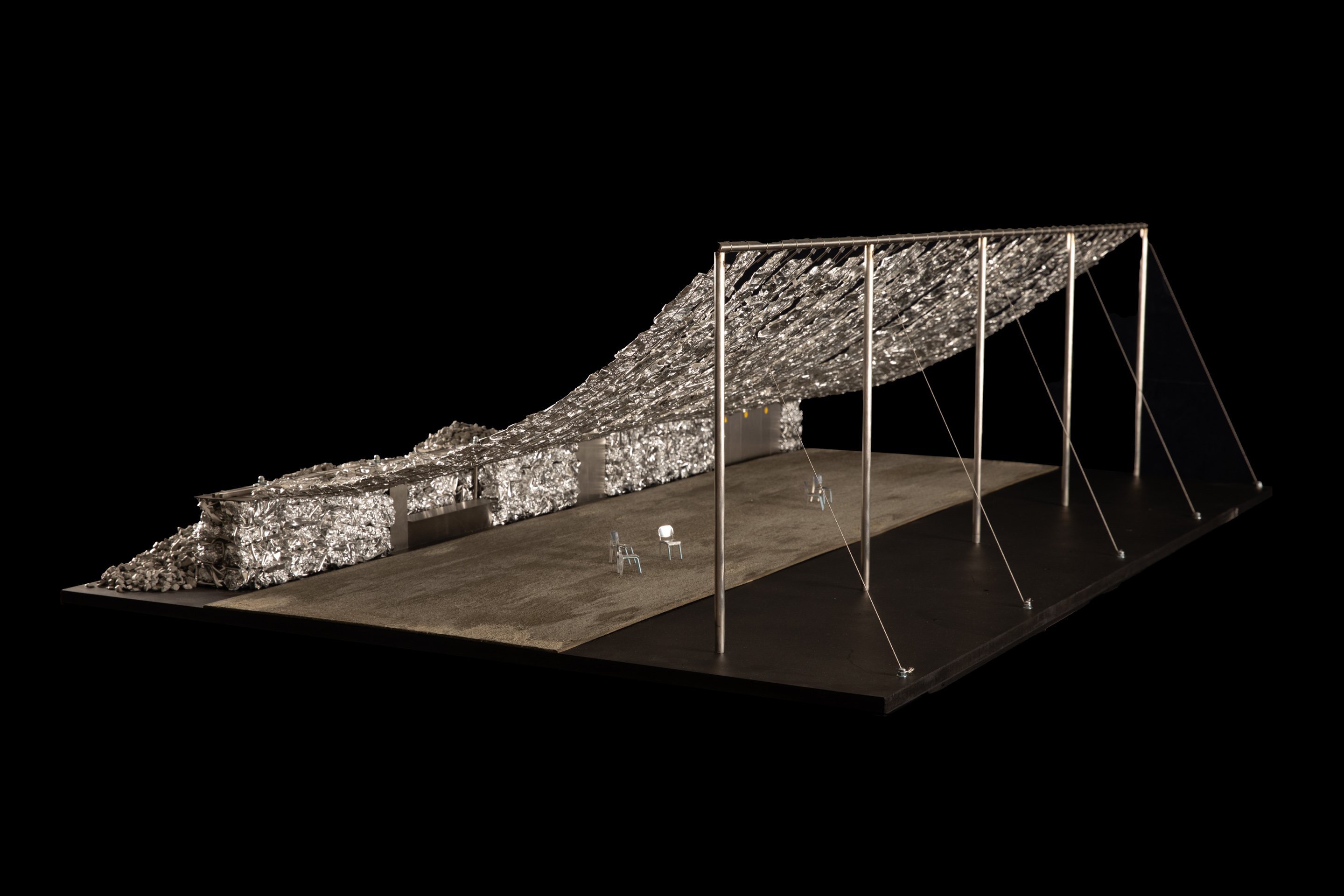

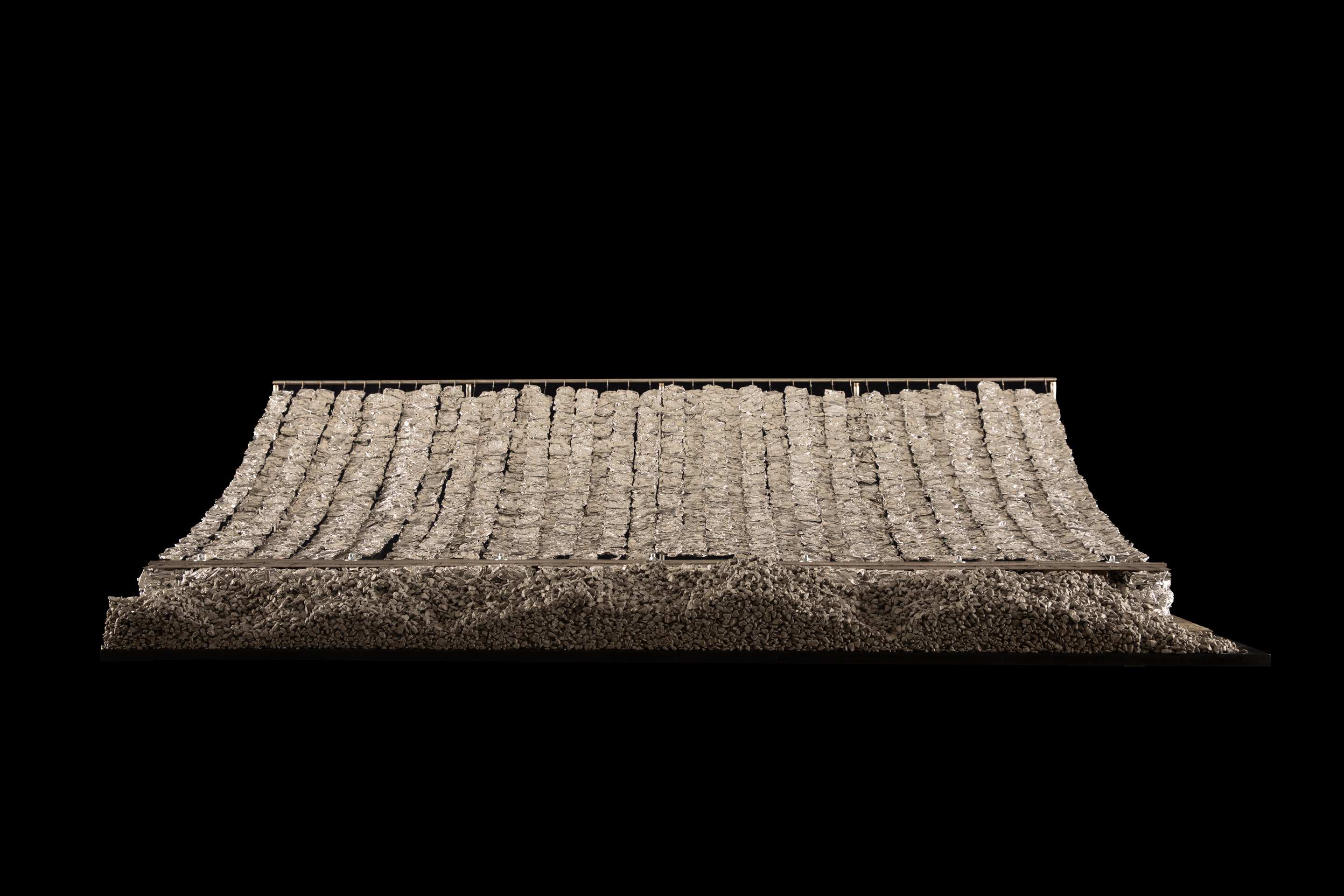

This thesis project explores how industrial byproducts can be repurposed architecturally without relying on energy-intensive recycling. This investigation raised the question: could the strongest form of aluminium exist – in its scrap state – without the need for melting? Discarded scrap was catalogued by size, shape, and thickness. This classification sparked the search for a low-energy method of recombination. Compression emerged as the key: by pressing scraps, blocks could be formed while saving up to 98% of the energy compared to melting, thus pausing the material cycle rather than continuing it. This process produced a lightweight, high-performance panel made entirely from scrap. The next step was to test how these blocks and panels could be combined into a cohesive structural system. The result was a design language uniting mass and lightness within a single constructive strategy. This project addresses a global challenge – the accumulation of industrial byproducts – and reframes it as an opportunity for architectural innovation.